SESI is hiring for Geotechnical, Environmental, and Site Civil positions. Apply Now!

2017 Metro BCA Recognizes SESI for Best Engineering Designs

September 12, 2017

SESI Consulting Engineers was recently recognized by the Metropolitan Builders and Contractors Association of New Jersey (Metro BCA) for the engineering designs for two sites: Harbor Square along the Hudson River waterfront, in Ossining, NY and BridgePort Logistics Center, in Perth Amboy, New Jersey.

Harbor Square – Ossining, New York

Harbor Square – Ossining, New York

Best Site Design, Waterfront

The Harbor Square project features 188-units of residential apartments and a 100-seat restaurant with views of the Hudson River. This building offers beautiful living spaces with many amenities and it is adjacent to the Ossining train station, making it ideal for commuters. The residential building boasts immediate access to a public park, outdoor theater, and a restaurant. Residents can take a stroll across the park to the 5,000-square-foot restaurant with a garden deck, outdoor beer garden, and sunset terrace.

The project site is in the New York State Brownfield Cleanup Program (BCP) and was originally a petroleum tank farm that required extensive remediation including source removal (UST’s), soil excavation and removal, pumping of groundwater, and installation of a site-wide capping system. A passive vapor extraction system was designed and installed in the structures. A floodplain development assessment was completed that included a no-adverse-impact analysis. Catch basins and Contech Vortech devices were used to capture and treat runoff from the roof and parking areas, to help with stormwater quality management. The residential building was constructed on piles and the restaurant on spread footings following a surcharge. Site Design, Permitting, Stormwater Management, Geotechnical, and Environmental design services were provided by SESI Consulting Engineers. SESI also provided full-time construction observation during the environmental cleanup and building/site construction.

BridgePort – Perth Amboy, NJ

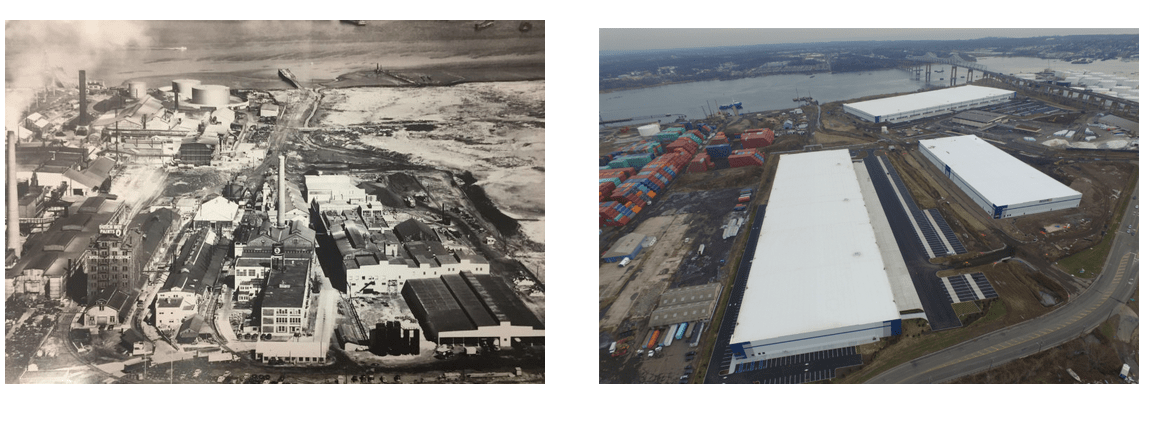

Best Engineering Design, Brownfield Redevelopment

The BridgePort Logistics Center is located just north of the Outerbridge Crossing in the City of Perth Amboy, Middlesex County, New Jersey. The project involved the multi-media remediation and subsequent redevelopment of the 105-acre former industrial site. The site was developed in the late 1800’s by American Smelting and Refining Company (ASARCO) and National Lead, who operated a secondary lead smelting operation and paint manufacturing facility on the property known as Dutch Boy Paints. Most of the original property consisted of tidal wetlands which were filled in with as much as 25 feet of industrial slag produced from the various on-site operations; mostly from ASARCO’s primary facility to the north of the Site.

A remedial investigation was completed from 2006 to 2007 and a remedial action workplan was developed by SESI Consulting Engineers in 2008. Concurrently, SESI Consulting Engineers assisted a developer in reaching a remediation cost settlement between the NJDEP and the responsible parties. However, as a result of the 2008-2009 economic downturn, interest in the property was suspended. Interest in the property eventually was renewed in 2013 when the NJDEP and the City of Perth Amboy worked closely with VPGS LLC—a joint venture of Viridian Partners and Goldman Sachs—to make the project a reality. Following a $25M remediation, the ePort Redevelopment was purchased by Bridge Development Partners. Bridge Development has completed the first of three industrial warehouse buildings at the Site totaling approximately 1.29 million square feet.

The Property was affected by the widespread distribution of smelting slag and other waste materials, which exhibited contamination by priority pollutant list (PPL) metals: primarily arsenic, antimony, and lead. The intent of the remedial action was to reduce the exposure of Site contaminants, including slag, to human and ecological receptors, groundwater, a tidally-influenced waterway running though the center of the Site known as Cranes Creek, and the Arthur Kill. The remediation consisted of a coordinated multi-faceted approach to reduce mass loading of contaminants to surface water by removing and/or containing contaminated source materials, restricting the movement of groundwater flowing through the residual slag fill, construction of engineering controls to minimize exposure to underlying residual slag and to minimize the infiltration of precipitation to groundwater, and reducing the contaminant concentration in groundwater at the surface water interface.

SESI also provided geotechnical engineering services at the BridgePort Redevelopment project. The geotechnical improvements consisted of the installation of wick drains; pre-loading of building areas with surcharges; improvement of the uncontrolled fills with deep dynamic compaction (DDC); and placement of conventional controlled, roller-compacted fill. In addition, a controlled modulus column (CMC) system was constructed throughout approximately half of the building C footprint. SESI provided geotechnical design, project management, and field oversight services throughout the project.

The following is a summary of remedial actions which were implemented at the Site:

(1) Excavation from below the water table and on-Site placement of highly impacted soil/slag containing lead, arsenic, and/or antimony;

(2) Site-wide engineered capping system to prevent direct human and ecological exposure to underlying residual soil/slag;

(3) Reduction of storm-water infiltration through residual soil/slag by routing storm water runoff from impervious cover to wet basins discharging directly to Cranes Creek and/or the Arthur Kill;

(4) Installation of a groundwater cutoff slurry wall around the Site;

(5) Removal of underground storage tanks (USTs) and remediation of impacted soil;

(6) Excavation and removal of material indicative of industrial or process waste, for off-Site disposal;

(7) Excavation and removal of battery casings for off-Site disposal;

(8) Delineation and remediation of PCB-contaminated soil in accordance with USEPA Region II Toxic Substance Control Act (TSCA) Regulations and NJDEP Technical Requirements;

(9) Excavation of Light Non-Aqueous Phase Liquid (LNAPL) stained and Total Petroleum Hydrocarbon (TPH) impacted soil; and,

(10) Removal of recoverable creosote product from the subsurface in the Former Creosote Plant Area.

Contact Justin Protasiewicz for more information- 973-808-9050.

Watch a great time lapse on Bridge Partner’s website.